Where Are Tesla Solar Panels Made? Inside the Gigafactory 2 in Buffalo, Tesla Solar Roof Systems

Tesla solar panels and solar roof tiles are manufactured at Gigafactory 2, Tesla’s sprawling solar cell and module production facility in Buffalo, New York. The factory has played a key role in Tesla Energy’s efforts to accelerate the world’s transition to sustainable energy through affordable, high-efficiency solar products integrated with battery storage.

Gigafactory 2, also known as RiverBend, is the primary production site for Tesla photovoltaic modules used in the Powerwall battery, commercial solar installations, and residential solar panel systems across the United States. Let’s take a closer look at Tesla’s solar manufacturing operations in Buffalo.

Tesla Repurposed a Defunct Solar Plant in Buffalo

The 1.2 million square foot facility now known as Gigafactory 2 has a circuitous history. It was originally built in 2014 by solar panel manufacturer Silevo as part of New York State’s Buffalo High-Tech Manufacturing Innovation Hub. SolarCity acquired Silevo and its Buffalo plant in 2014 shortly before Tesla CEO Elon Musk bid to take over SolarCity in 2016.

Tesla’s $2.6 billion acquisition of SolarCity closed in November 2016, folding the nation’s leading residential solar installer into Tesla just as Musk prepared to reveal the company’s groundbreaking solar roof tile technology. With Tesla needing high-volume manufacturing capabilities for its solar tiles, repurposing Silevo’s Buffalo solar panel fab as Gigafactory 2 became a natural choice.

Gigafactory 2 Timeline Overview

- August 2014 – Solar panel maker Silevo begins construction on South Buffalo manufacturing facility

- June 2016 – New York State invests $750M to build out the Silevo plant

- October 2016 – Tesla acquires Silevo parent company SolarCity

- November 2016 – Tesla merger with SolarCity closes

- December 2016 – Tesla announces solar roof product; plans to manufacture in Buffalo

- September 2017 – Tesla takes ownership of Buffalo plant, now ‘Gigafactory 2’

- October 2017 – First Tesla solar roof tiles produced in Buffalo

- August 2018 – Initial solar roof installations underway

What Products are Made in Gigafactory 2?

As Tesla’s primary US solar production facility, Gigafactory 2 manufactures photovoltaic cells and modules for the Powerwall battery and complete residential solar installations across America. The factory output supports both traditional solar panels along Tesla’s unique solar glass roof tiles.

Specifically, Gigafactory 2 production includes:

- Solar cells – The photovoltaic components that convert sunlight into renewable electricity

- Solar roof tiles – Tesla’s glass tiles embedded with solar cells to resemble conventional roofing

- Standard solar panels – Traditional flat panel solar modules installed on rooftops

- Powerwall solar panels – Solar-charged home battery for energy storage

Bringing all these manufacturing processes under one roof at Gigafactory 2 provides vertical integration efficiencies for Tesla Energy.

Local Hiring and Manufacturing Jobs in Buffalo

A key driver behind New York State’s massive investment in the Buffalo solar plant was promoting employment in the economically struggling region. Tesla’s acquisition of the facility came with lofty commitments to create thousands of local clean energy jobs.

After early struggles meeting hired targets and paying state penalties, Tesla now employs over 3,000 people in the Buffalo area across solar, energy storage, service and powertrain roles. The company expects to continue hiring as production scales further.

Gigafactory 2 has become a symbol of renewables-powered economic revitalization in Buffalo, establishing the city as a growing sustainability hub. Tesla and its CEO Elon Musk have become household names, exciting area youth towards STEM learning and future careers in solar technology and clean energy.

Ramping Solar Cell and Module Production

With module production lines increasingly hitting full utilization, Gigafactory 2 has seen its total solar output double over the past year. The facility can now produce over 1 Gigawatt worth of solar components annually – enough to power up to 150,000 homes.

This expanded Buffalo production has supported 25% year-over-year growth in Tesla solar deployments in the US as adoption accelerates. Overseas solar expansion relies on Tesla’s Gigafactory in Shanghai, but Buffalo remains the linchpin for American panel production.

Tesla’s Solar Cell and Panel Manufacturing in Buffalo, New York

While Tesla builds batteries in Nevada and electric cars in California and China, its solar cells and panels get primarily produced at Gigafactory 2 in Buffalo, New York. The sprawling facility along the banks of the Buffalo River handles end-to-end solar component fabrication for installations across America.

Specifically, Gigafactory 2 coordinates manufacturing of:

- High efficiency solar cells to convert sunlight into renewable electricity

- Complete solar panel modules ready for rooftop installation

- Glass solar roof tiles with integrated cells

- Custom solar components for Powerwall home batteries

Consolidating such critical solar production in Buffalo aligns with CEO Elon Musk’s vision to revitalize American manufacturing leadership through renewable energy technology.

Future Expansion Plans for Gigafactory 2

Even with recent production milestones, Tesla is still only getting started with US solar manufacturing. The company continues to install new automated equipment in Buffalo, further increasing solar cell, module, and roof tile capacity.

Constructing additional production lines will grow the facility’s footprint by almost 2 million additional square feet as Tesla aims to make enough solar components in Buffalo for up to 1 million rooftop systems per year at terawatt-scale. That’s over 30 Gigawatts of annual solar capacity – a 100x increase over today.

Gigafactory 2 has come a long way from its initial days as an abandoned SolarCity acquisition project. Its growth now serves as the blueprint for reviving struggling industrial regions across America with regenerative, renewables-powered employment anchored around combating climate change. Tesla’s solar ascent appears ready to lift Western New York towards a brighter future.

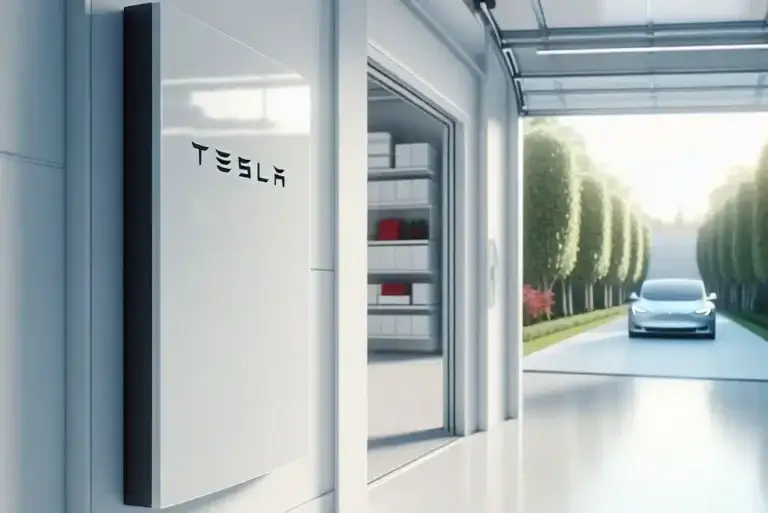

Integrated Energy Storage Production

In addition to solar components, Gigafactory 2 has expanded its renewable energy manufacturing footprint by producing Tesla battery storage systems onsite.

Installing production lines for Tesla’s Powerwall home battery and utility-scale Megapack integrates storage tightly with solar capabilities, enabling wider deployment of renewable energy that can be stored for nighttime use.

The co-located Powerwall line can produce enough home energy storage units to equip 50,000 houses with solar-charged batteries every month. Meanwhile, the Megapack factory feeds the growing demand from electricity providers for giant batteries that improve grid resilience and reliability.

Bringing both solar and storage production under one roof at the Buffalo facility aligns with Tesla’s broader vision of accelerating global sustainable energy adoption.

Strengthening US Energy Independence

With electric vehicles transitioning away from gasoline and solar/storage solutions gaining traction for home energy needs, Tesla’s growing domestic manufacturing is helping the United States reduce its reliance on fossil fuels.

Gigafactory 2 has become an anchor facility strengthening American energy independence through locally produced renewable technologies. Beyond boosting national security, the solar panels and batteries made in Buffalo will facilitate wider adoption of clean energy necessary to combat climate change.

Tesla expects to soon produce 1 Gigawatt-hour worth of batteries every day in Buffalo – enough to power over 9,000 homes. Combine such exponential storage growth with rising solar module output and Tesla is primed to disrupt outdated power infrastructure across the country.

Job Creation Tops 3,000 and Counting

After receiving substantial incentives from New York State tied to employment promises, Tesla struggled in early Buffalo days to meet hiring targets.

Layoffs and high-profile departures painted an uncertain picture as production slowly ramped. But fast forward to today and the tide has clearly turned, with Tesla announcing over 3,000 workers now spread across various Buffalo roles.

And the local job surge is really just beginning. As production scales further and Tesla expands Gigafactory 2 to nearly 3.5 million square feet over coming years, Buffalo area headcounts are projected to top 4,000, 6,000, or even 10,000 if solar ambitions are fully realized.

Investing in the Green Leaders of Tomorrow

To fuel its ambitious growth plans, Tesla recognizes the importance of investing not just in factory infrastructure but also in human capital – the workers powering a renewable energy future.

The company aims to develop Buffalo’s workforce through multiple skills training initiatives at area community colleges and within K-12 school districts. By engaging students around exciting local opportunities, Tesla strengthens its talent pipeline early and raises awareness of promising solar energy careers.

Grooming green job seekers of tomorrow is central to Tesla cementing itself as a magnet employer in Western New York. Solar technicians and clean energy manufacturing roles near Buffalo offer income mobility today while moving society positively toward environmental sustainability.

Final Thoughts

Tesla’s sprawling Gigafactory 2 solar production campus symbolizes the potential for renewables-based manufacturing to transform economically depressed regions. As Buffalo drives towards a cleaner energy paradigm, the installed solar capacity and battery storage output scaling locally will ripple outwards across surrounding communities.

With Tesla solar roof orders now backing up years into the future even before completing plant expansions, the company’s integrated energy solution resonates widely. Innovative consumer products built sustainably in America have market appeal while aligning economic incentives with solving humanity’s climate challenges.

Thanks to the momentum of Tesla’s Buffalo solar gigafactory, the future for renewable energy looks increasingly bright. Gigafactory 2 provides a blueprint for reviving American manufacturing prowess through green technology leadership – one locally produced solar tile and battery pack at a time.

Frequently Asked Questions

What solar products are made in Buffalo?

Tesla’s Gigafactory 2 facility in Buffalo, NY produces solar cells, solar roof tiles, traditional solar panels, and Powerwall battery solar panels. It manufactures many of the solar components used by Tesla Energy in the United States.

How many solar panels can the Buffalo plant produce annually?

The current output capacity of Gigafactory 2 is over 1 Gigawatt worth of solar cells and modules per year. At maximum targeted utilization levels, the factory aims to eventually produce enough solar components for 1 million home solar installations per year.

How many jobs has the Tesla plant created?

As of early 2022, Tesla employs over 3,000 workers in various roles across solar, energy storage, service and powertrain manufacturing in the Buffalo area. More jobs are expected as production scales up.

Does Buffalo just make solar products?

No, in addition to solar components, Gigafactory 2 has added production lines for Tesla’s Powerwall home battery and Megapack utility-scale battery. The co-location of solar, battery storage, and powertrain equipment manufacturing helps advance Tesla’s integrated sustainable energy solutions.

What incentives did Tesla receive to build in Buffalo?

New York State committed $750 million in investments to construct the original facility later acquired by Tesla. The incentives aimed to revive manufacturing and create jobs in the struggling Buffalo regional economy.